Are you looking for a material that stands up to a lot of wear and tear, maybe for a construction project or even for something like a vehicle floor? It's almost like trying to pick the right family SUV for 2025, isn't it? You want something that will serve your family well for years, and the same goes for materials you build with. There are so many options out there, and it can feel a bit confusing, just like those many vehicle choices. This guide aims to clear things up for you.

When you're searching for something that offers both strength and a smooth finish, filmi ply often comes up. It's a type of plywood that has a special coating, giving it unique properties. This material is pretty popular in various industries, and for good reason, too. It’s known for its ability to handle tough conditions, which is why people keep coming back to it.

We’re going to really look at what makes filmi ply so useful, where it shines, and how you can pick the best kind for your needs. We’ll also touch on how it stacks up against other materials, and honestly, how to make it last a good long while. Think of it like our testing team looking at over 200 data points when rating vehicles; we’ll give you the information you need to find the best material for you quickly and easily.

Table of Contents

- What Exactly is Filmi Ply?

- Why Filmi Ply Matters: Its Many Uses

- Choosing the Right Filmi Ply: What to Look For

- Making Your Filmi Ply Last

- Filmi Ply vs. Regular Plywood: A Quick Look

- Finding Your Best Fit

- Frequently Asked Questions About Filmi Ply

What Exactly is Filmi Ply?

Filmi ply, sometimes called film-faced plywood, is a special kind of plywood. It has a thin, smooth film, usually made of phenolic resin, pressed onto its surfaces. This film gives the plywood a lot of extra protection. It’s very different from just regular plywood, you know.

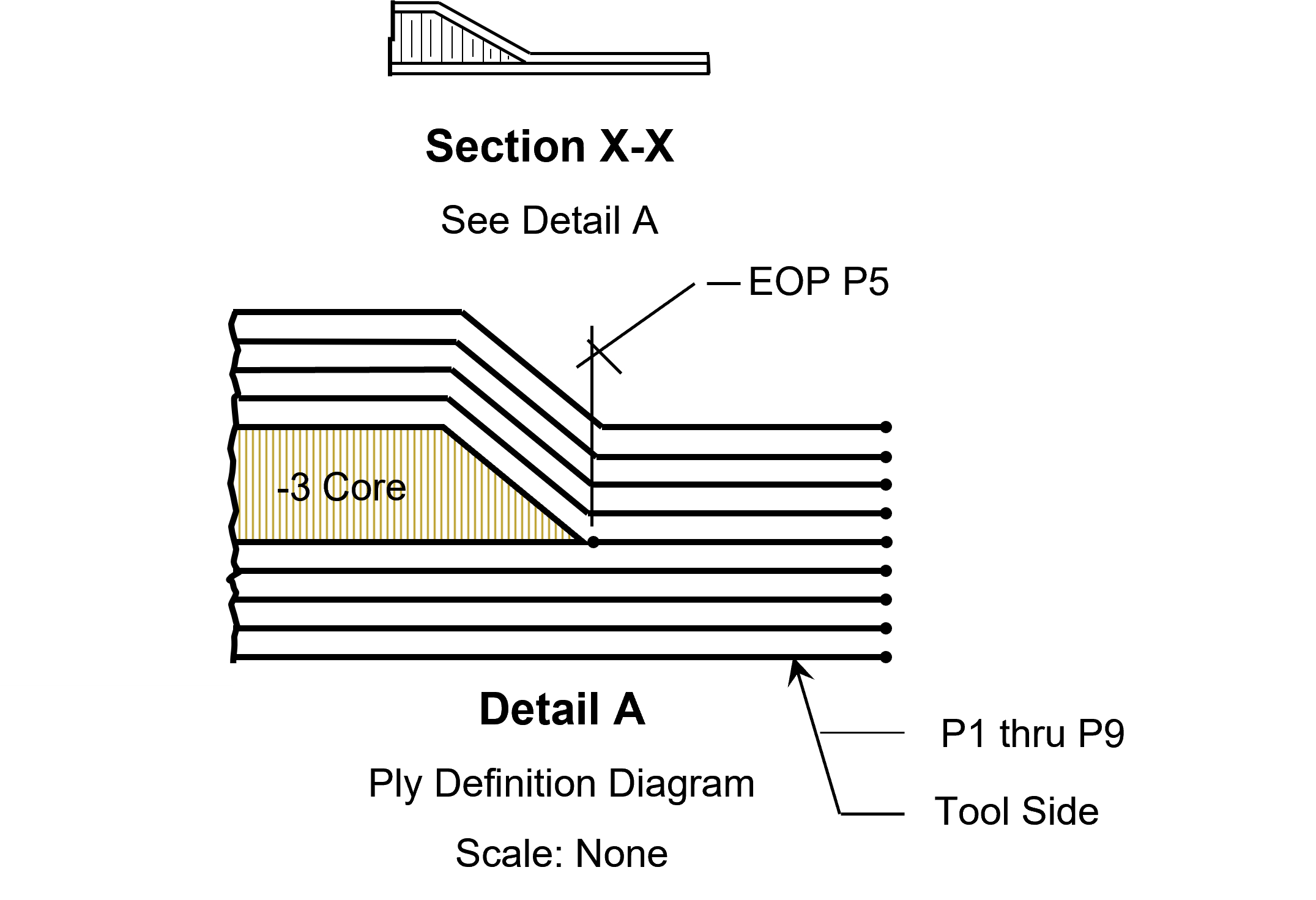

The core of filmi ply is still made from layers of wood veneer, just like standard plywood. These layers are glued together with a strong adhesive. The outer film is the key feature, though. It makes the surface much more resistant to water, chemicals, and general wear. It's really quite tough.

This film also gives the board a very smooth finish. This is why it’s so popular in certain applications where a clean, even surface is important. It’s basically a super-tough version of plywood, designed to handle more demanding jobs. So, it's pretty specialized.

Why Filmi Ply Matters: Its Many Uses

Filmi ply is used in a lot of places because of its strong features. Its durability and smooth surface make it a go-to material for many different projects. You see it in big construction sites and also in smaller, more detailed work. It’s pretty versatile, actually.

The fact that it can resist moisture and chemicals is a big plus. This means it holds up well in conditions where other wood products might quickly fall apart. It’s also fairly easy to clean, which is a nice bonus. This makes it a really practical choice for many situations, you know.

It’s also often reusable, especially in certain applications. This can save a lot of money over time. Just like finding a vehicle that offers good fuel economy, using a material that you can use again and again is a smart move. It’s a very cost-effective option in the long run, in a way.

Building Strong Foundations: Concrete Formwork

One of the most common uses for filmi ply is in concrete formwork. When you pour concrete, you need a mold to shape it. Filmi ply is often chosen for this job. Its smooth surface helps create a very clean and even concrete finish, which is important for quality.

The film on the plywood prevents the concrete from sticking to it too much. This makes it easier to remove the forms once the concrete has set. It also means you can reuse the same boards many times, which saves on material costs. This is a big deal on construction sites, you know.

It stands up well to the moisture and alkalinity of fresh concrete. This means the forms stay strong and stable during the curing process. For builders, this reliability is pretty important. It’s a truly essential material for pouring strong foundations, actually.

Tough Surfaces: Vehicle and Industrial Flooring

Filmi ply is also really good for flooring in vehicles, like trucks, buses, and even trailers. The surface is very resistant to scratches and impacts. This makes it perfect for areas that see a lot of heavy use and traffic, just like the floor of a busy family SUV, in a way.

It’s also used for industrial flooring in warehouses or factories. Where things might get dropped or where there’s a lot of movement, this material holds up well. Its water resistance also helps protect the floor from spills and moisture. It’s a pretty smart choice for these kinds of places.

The non-slip properties of some filmi ply types are also a benefit for these applications. This adds a layer of safety for people and goods moving around. It’s about creating a safe and durable surface, which is always a good thing. So, it really serves its purpose there.

Other Clever Applications

Beyond concrete and flooring, filmi ply finds its way into other interesting places. You might see it used for playground equipment because of its durability and smooth finish. It's safe for kids, and it lasts a long time outdoors. That's a pretty good use for it, you know.

It’s also used for temporary structures, like event stages or stands. The ease of assembly and disassembly, combined with its strength, makes it ideal. It can be set up quickly and then taken down and stored for later. It’s pretty convenient, honestly.

Sometimes, it’s even used in furniture that needs to be extra tough, like workshop benches or outdoor seating. The protective film helps it resist wear and tear from tools or weather. It’s a very adaptable material, you know, for a lot of different projects.

Choosing the Right Filmi Ply: What to Look For

Picking the right filmi ply is a bit like choosing the best vehicle for your family. You need to look at many different points, not just the price. Our testing team looks at over 200 data points when rating vehicles, and you should consider many factors for your plywood, too. It’s about matching the material to the job.

You’ll want to think about where you’re going to use it and what kind of stress it will face. Is it for a one-time project or something that needs to last for years? These questions will help guide your choice. It’s pretty important to get this right, you know.

The quality of the film, the type of wood in the core, and the thickness all play a part. Getting this selection correct means your project will be stronger and last longer. It’s about making a smart investment, really.

Understanding Grades and Quality

Filmi ply comes in different grades, which tell you about its quality and how it's made. Higher grades usually mean a better-quality film and a more consistent wood core. This can affect how many times you can reuse it, for example, in formwork. It’s pretty much like vehicle ratings; higher ratings often mean better performance.

Look for information on the type of film used. Phenolic film is common and very durable. Some films might be designed for specific uses, like extra slip resistance. Knowing this helps you pick the right one for your specific needs, you know.

The quality of the adhesive used to bond the layers is also important. A good adhesive means the ply won't delaminate, even in wet conditions. This is a key factor for its long-term performance. It’s a rather critical detail, actually.

Thickness and Size Considerations

Filmi ply is available in many different thicknesses, just like different sizes of tires for a car. The right thickness depends on the load it needs to support and how much bending it might experience. Thicker boards are generally stronger but also heavier and more expensive. So, you have to balance strength with practicality.

Common thicknesses range from about 9mm to 21mm, but you can find others. For concrete formwork, the thickness affects how much support you need behind the board. For flooring, it impacts how sturdy the surface feels. It’s a very practical decision, you know.

Sizes also vary, typically in standard sheets. Knowing the dimensions of your project helps you minimize waste when cutting. Planning this out can save you time and money. It’s a pretty sensible approach, really.

Core Material Matters

The wood used for the core layers of filmi ply can be different. Poplar, birch, and eucalyptus are common choices. Birch plywood cores are often considered very strong and stable, making them a premium option. Poplar might be lighter and more economical, though. It's a bit like choosing between different engine types for a vehicle, each with its own benefits.

The quality of the core affects the overall strength and stability of the board. A core with fewer voids or gaps will perform better and last longer. This is especially true if the board will be exposed to moisture. It’s a rather important detail for durability, you know.

Sometimes, the core might even be made from mixed woods or other engineered wood products. Understanding the core material helps you predict how the filmi ply will behave under different conditions. It’s pretty much about knowing what’s inside, actually.

Making Your Filmi Ply Last

To get the most out of your filmi ply, especially if you want to reuse it, proper care is important. After use, especially in concrete formwork, clean the surfaces thoroughly. Remove any concrete residue or dirt. This helps keep the film intact and ready for the next job. It’s a bit like maintaining your vehicle to keep it running well for years.

Store filmi ply flat and in a dry place, away from direct sunlight or extreme temperatures. Stacking it properly prevents warping and damage. Protecting the edges is also a good idea, as they can be more vulnerable to moisture. This kind of care really extends its lifespan, you know.

When handling the boards, avoid dragging them or dropping them on their edges. Sharp impacts can chip the film, which then reduces its protective qualities. Gentle handling means it will serve you well for many uses. It’s a very simple step that makes a big difference, honestly.

Filmi Ply vs. Regular Plywood: A Quick Look

The main difference between filmi ply and regular plywood is that special film coating. Regular plywood has a wood veneer surface that is usually sanded smooth. Filmi ply has that resin film, which changes its properties quite a bit. It’s a pretty clear distinction, you know.

Filmi ply is much more resistant to water, chemicals, and abrasion than regular plywood. This makes it suitable for outdoor use or wet environments where regular plywood would quickly degrade. Regular plywood will swell and delaminate much faster when wet. So, it's a big step up in terms of resilience.

Because of its enhanced durability and specialized surface, filmi ply often costs more than standard plywood. However, its reusability and longer lifespan can make it more economical in the long run for certain applications. It's about value over initial price, similar to how you look at the total cost of ownership for a vehicle. Learn more about plywood types on our site.

Finding Your Best Fit

Choosing the right filmi ply for your project means thinking about its specific demands. Just like our guide to the best 3-row SUVs helps you find the right vehicle for your family, this information should help you pick the best material. Consider the environment it will be in, the loads it will bear, and how often you plan to use it. It’s pretty much about matching the tool to the task.

Remember that the results of acoustical tests are also included for vehicles where relevant, and while filmi ply isn't usually about sound, its density and structure do play a role in material performance. You want something that performs well in its intended purpose. If you're looking for fire and sound rated assembly information, the AG Design Library is a robust tool, and UL Solutions has developed guides for various parties. This highlights how important detailed specifications are for materials, and filmi ply is no different.

Taking the time to understand the grades, core materials, and film types will really pay off. It ensures you get a material that will serve your project well for years. It's about making a choice you feel good about. And you can always learn more about other durable construction materials here.

Frequently Asked Questions About Filmi Ply

What is filmi ply used for?

Filmi ply is primarily used for concrete formwork, vehicle flooring, industrial flooring, and other applications needing a durable, smooth, and water-resistant surface. It's quite versatile, actually, for tough jobs.

How long does filmi ply last?

The lifespan of filmi ply depends on its quality, how it's used, and how well it's cared for. In concrete formwork, higher-quality boards can be reused many times, sometimes dozens of times. For permanent installations like vehicle floors, it can last for many years with proper maintenance. It’s a pretty durable material, you know.

What is the difference between filmi ply and regular plywood?

The main difference is the special phenolic resin film coating on filmi ply, which regular plywood lacks. This film makes filmi ply significantly more resistant to water, abrasion, and chemicals, giving it a smoother surface and often allowing for multiple reuses. Regular plywood has a raw wood veneer surface. So, it's a pretty big distinction in terms of performance.

Detail Author:

- Name : Paige Steuber

- Username : zsenger

- Email : ila28@gmail.com

- Birthdate : 1993-06-05

- Address : 92710 Ally Manors Apt. 698 Port Isabelle, KS 36467-9532

- Phone : 1-785-539-9471

- Company : Lind, Lindgren and Lubowitz

- Job : Food Batchmaker

- Bio : Modi consequuntur voluptatibus minima aliquid vitae temporibus blanditiis. Nihil eligendi consequatur ut. Minima officiis unde facilis. Voluptates voluptate mollitia dolor inventore.

Socials

tiktok:

- url : https://tiktok.com/@amely_legros

- username : amely_legros

- bio : Tempora quam sed ea distinctio aspernatur. Eius consequatur rerum qui.

- followers : 3549

- following : 14

instagram:

- url : https://instagram.com/amelylegros

- username : amelylegros

- bio : Sunt laboriosam dolore eos molestiae quaerat. Excepturi qui magni dolores asperiores ut.

- followers : 1570

- following : 2948

linkedin:

- url : https://linkedin.com/in/legros1982

- username : legros1982

- bio : Fugit minus quod et quisquam sint minus.

- followers : 1016

- following : 2276